Scroll down

Scroll down

Scroll down

What is Carbon Black?

Sustainable Resource of the Future

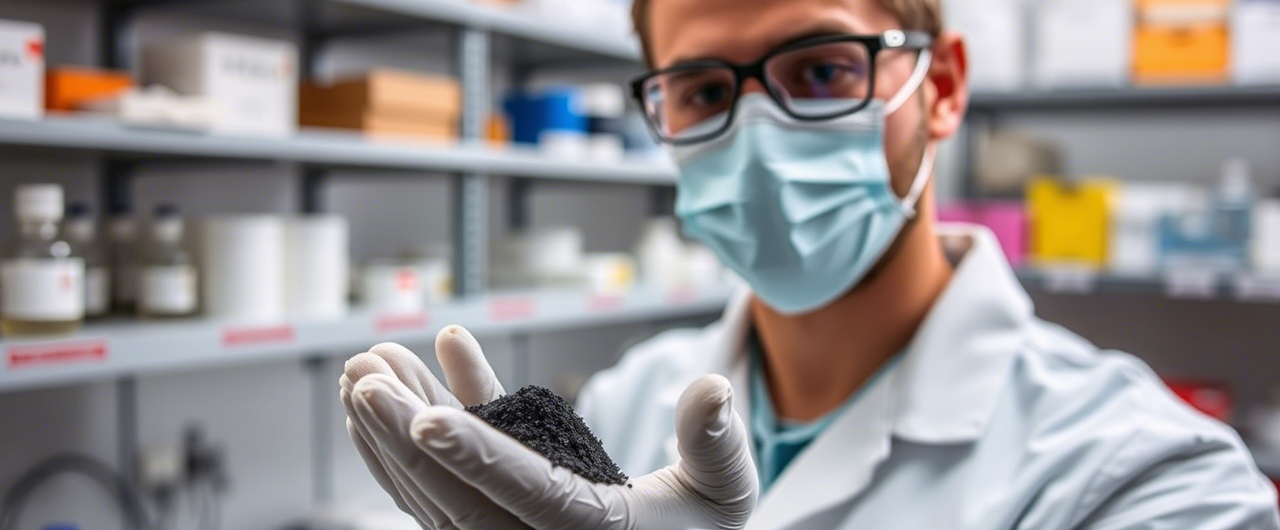

Carbon black from tire pyrolysis is a solid, black carbon material produced by thermal decomposition of rubber without oxygen. It mainly contains carbon, small amounts of ash, metals, and organic substances, and its properties resemble technical carbon black. After purification and grinding, it can become a substitute for technical carbon black, widely used in tire production, rubber products, plastics, and pigments.

What Makes Technical Carbon Black Special?

Source and Availability:

Used tires are a common and convenient raw material for producing technical carbon black, ensuring stable availability.

High Quality:

Although carbon black contains about 20% less pure carbon than virgin carbon black (due to mineral fillers), its properties in industrial applications – especially rubber – are comparable to several types of virgin technical carbon black.

Sustainable Development:

Producing carbon black reduces CO₂ emissions by over 80% compared to virgin technical carbon black.

Replacing just 10% of global virgin technical carbon black production with RCB (Recovery Carbon Black) would reduce annual emissions by 2.7 million tons of CO₂.

Versatility:

RCB is used in tire manufacturing, rubber industry, plastics, and as a technical pigment.

Technology and Quality

TEF offers RCB produced through an advanced and fully controlled technological process – from tire preparation, through unique pyrolysis, to final processing. The internal testing laboratory ensures consistent product quality and compliance with industrial specifications.

Industrial Direction

In the era of decarbonization and growing environmental demands, the tire industry is actively replacing virgin technical carbon black with recovered carbon black. This is a real response to the need for circularity, emission reduction, and better utilization of waste materials.